Adrian from Adrian’s Digital Basement has shifted focus from his usual vintage PCs to bring an Amiga 1200 restoration project to the main channel. Donated by James, a long-time supporter who previously sent over several Ataris, this machine arrived in pieces, yellowed, and with a damaged case. True to its era, the Amiga 1200 suffered from leaking surface-mount capacitors—an issue known as capacitor plague—that can cause severe board damage if left untreated.

Despite its rough condition, Adrian sees potential. The computer includes spare parts, an accelerator card, and even a brand-new blue replacement case from A1200.net. It’s a full challenge: repair, restore, and revive one of Commodore’s last great wedge computers.

Diagnosing the Damage

The Amiga 1200 restoration project begins with exploration. Inside the case, Adrian finds corroded capacitors, bent shielding, and missing pads. The board also shows evidence of earlier repair attempts—likely abandoned once traces began lifting. Using his preferred “wiggle method,” Adrian removes the old capacitors, cleans corroded areas, and replaces the damaged connections with new leads.

Each capacitor comes off carefully, replaced with modern equivalents. A bit of flux, a fine soldering tip, and patience bring the board back to life. Where traces had lifted, Adrian uses small copper offcuts to reestablish connections, ensuring solid electrical contact. Once recapped and cleaned, the Amiga looks remarkably better.

First Power-Up

With repairs done, Adrian connects his modern Amiga power supply and video output to test the system. At first, there’s only a black screen—never a comforting sign. After a few checks with his oscilloscope, he confirms voltage is present, and the ROM chips have life. Suddenly, the screen flickers to purple, then displays the familiar Workbench floppy prompt. The Amiga lives.

A quick recap of the test setup shows that the issue wasn’t the machine at all—it was the external video converter being finicky. The board itself powers up cleanly and stays stable. That alone makes the night’s soldering effort worthwhile.

Testing Drives and Memory

Next, Adrian turns his attention to the floppy drive, connecting it with a standard PC-style ribbon cable. A cleaning disk whirs, and the drive responds perfectly. Running Amiga Test Kit confirms 2 MB of working chip RAM, solid audio playback, and no CIA chip issues. The audio output, playing “Spice It Up” by Jester/Sanity, sounds flawless.

However, the keyboard connector lacks its locking tab, forcing Adrian to improvise with plastic shims to hold the ribbon cable in place. It’s a temporary fix, but it works—every key registers after a few adjustments. With the keyboard functional, the Amiga 1200 is fully interactive again.

Rebuilding the Case

The next task is cosmetic. The original beige case is cracked and warped, its keyboard heavily yellowed. The new A1200.net case, molded in dark blue, is a striking replacement. It includes a new trapdoor, internal metal screw inserts, and even an engraved signature panel inside the shell.

Adrian transfers the original metal Commodore badge, replacing the cheap replica sticker that came with the kit. A few missing screws slow progress, but soon the motherboard, floppy drive, and hard drive are securely mounted. The only setback is a missing eject button for the drive—an issue to revisit later.

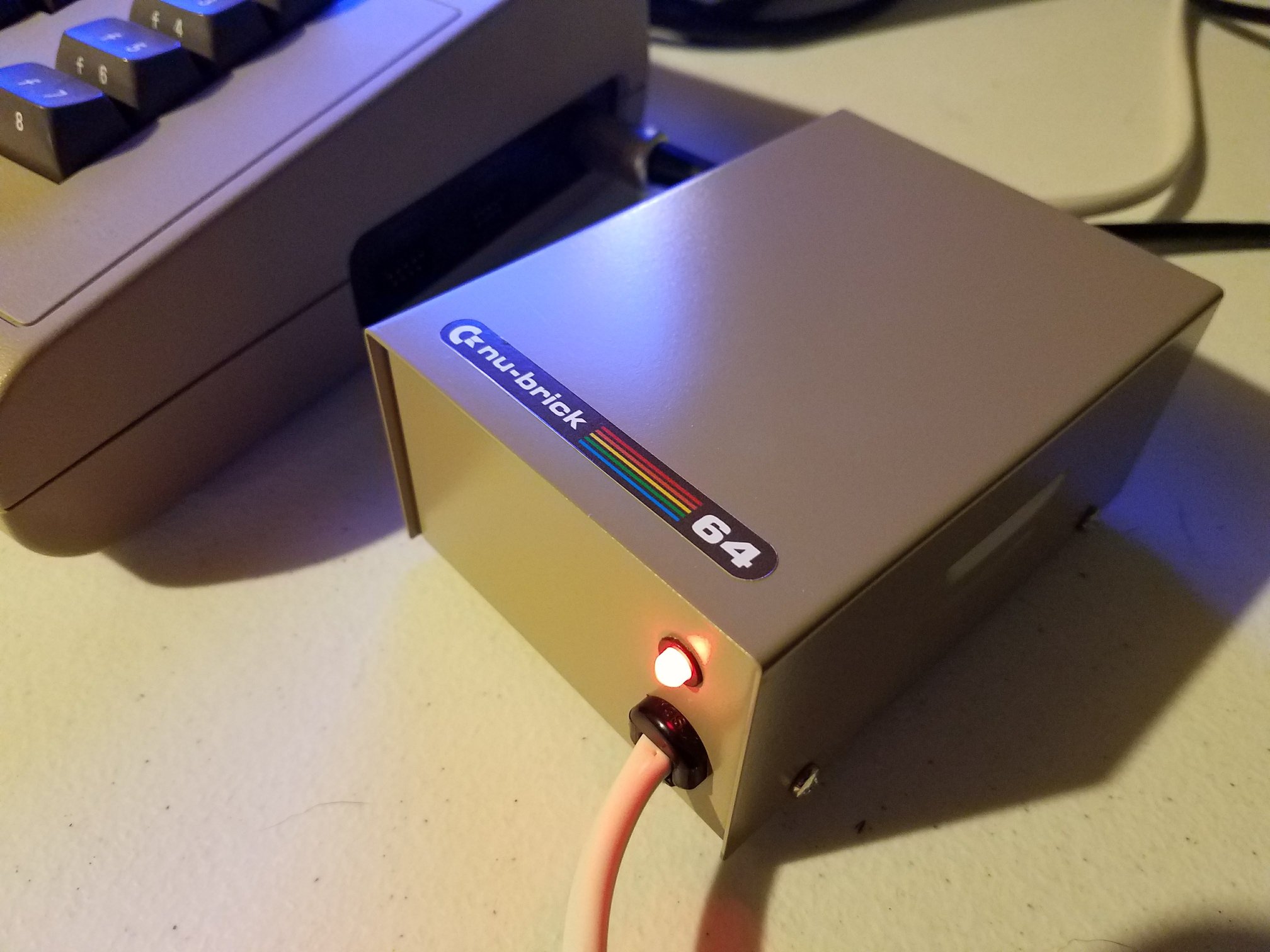

The Power Supply Problem

When the system first boots in its new case, the screen dims every time the floppy drive clicks. Adrian suspects voltage sag on the 12-volt line. Switching from a modern power brick to his trusted Mean Well-based supply solves the problem immediately. The machine now runs steady and quiet, with stable video and sound output.

With a working hard drive installed—a silent 4 GB Seagate model—the Amiga boots straight into Workbench 3.0. The older original drive had failed, but this modern replacement brings instant results.

Seeing AGA in Action

To test graphics, Adrian loads 256-color images and classic software like Deluxe Paint. The AGA chipset’s capabilities shine—smooth multitasking, vivid palettes, and fluid transitions between screens. Mod music plays in the background while multiple programs run simultaneously, showing off the multitasking magic that once set the Amiga apart.

Performance testing shows expected results: 1.04x the original Amiga 1200 speed, with 1.5 MB per second hard drive transfer rates. The system performs exactly as a healthy stock A1200 should.

Loading Up Some Games

No Amiga repair video would be complete without a gaming test. Adrian loads The Chaos Engine, one of the most celebrated Bitmap Brothers titles. The AGA version looks rich and colorful, with fluid animation and sharp detail. Even though the controls take some getting used to, the gameplay runs as expected. Occasional slowdown hints at what an accelerator could fix—a topic saved for the next video.

Looking Ahead

With the machine running beautifully, Adrian reflects on its journey. What began as a pile of parts and corroded boards is now a functioning Amiga 1200, restored to its full glory. The Amiga 1200 restoration project highlights why these machines remain beloved—durable, repairable, and endlessly fascinating.

Adrian plans to install the ACA 1221 accelerator next, unlocking faster speeds and additional RAM. Once complete, the system will be ready for WHDLoad installations, allowing hundreds of games to run directly from the hard drive.

Final Thoughts

Adrian’s Digital Basement continues to show why the retro computing community thrives on generosity and curiosity. Thanks to James’s donation, another Amiga has been saved from decay. The new blue case may not be original beige, but it symbolizes renewal—a fresh start for a computer nearly lost to time.

Fans eager to watch every solder joint, discovery, and surprise can catch the full restoration video on Adrian’s channel. It’s an entertaining mix of technical repair and nostalgia, showcasing both the fragility and resilience of Commodore’s final wedge machine.