Gideon’s Logic, known for popular products like the Ultimate-II+ cartridge and Ultimate 64 Elite boards, has provided an update on the Ultimate 64 Elite-II project.

For the pre-orders, the initial deposit of €1 has been adjusted to a more realistic amount following quotes from the factory. All pending orders will soon reflect the latest images, descriptions, and pricing. If your order currently shows a ‘Failed’ status, it will be reset to ‘PreorderPendingPayment.’ There’s no need to cancel your original order or place a new one, and payment will only be requested once mass production begins.

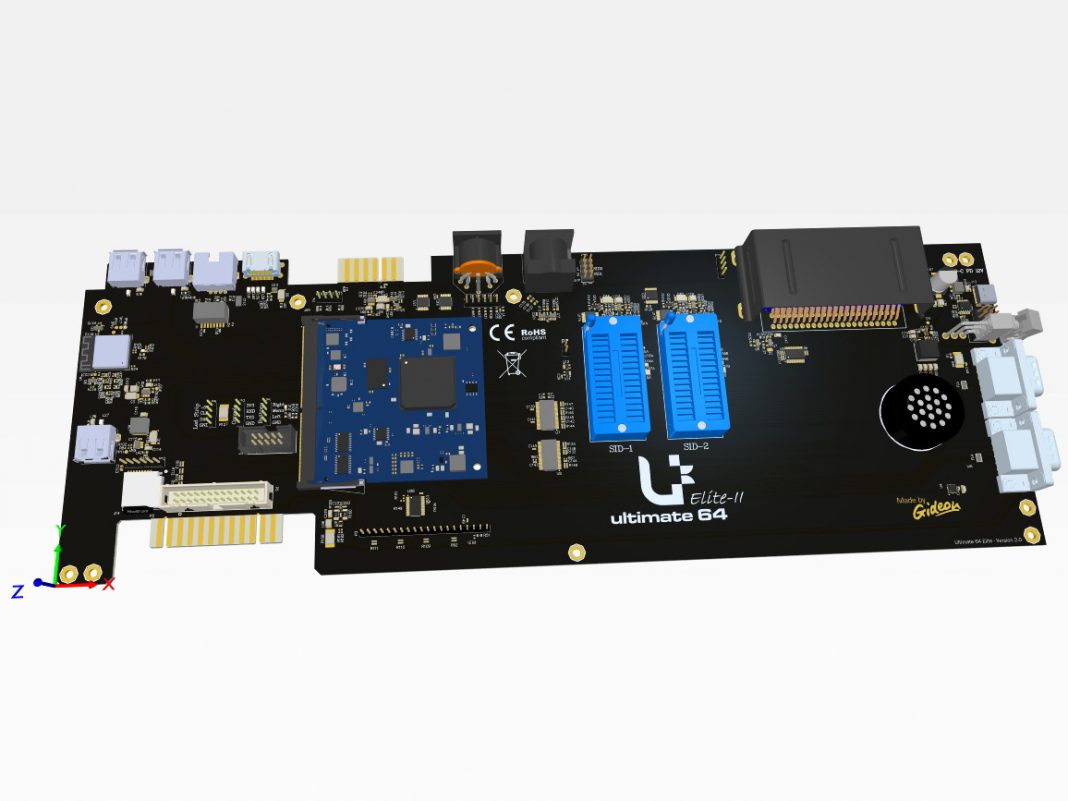

Regarding the progress on the Ultimate 64 Elite-II mainboard project, significant strides have been made. By May, all preparations were completed, and the specifications for the new Ultimate 64 were finalized. The new design will feature two boards: a large C64-C style board with connectors and SID sockets, and a smaller ‘engine’ board housing the FPGA and high-speed logic. This modular approach allows for easy form factor changes or engine replacements if parts become unavailable.

In June, five prototypes of this board set were produced at a quick-turnaround factory. Due to component availability, these prototypes were partially populated, and additional parts were manually soldered onto two of them. Given the differences in design from the original Ultimate 64, particularly in implementation, significant effort was required to get the new board operational. Some minor electrical and mechanical design flaws were discovered but were resolved through workarounds—exactly what prototypes are for. These issues have since been corrected in the updated schematics and layout.

As for delivery, the target is to ship before the end of the year. The FPGAs and other necessary components for 1,000 board sets have already been procured by the chosen factory. Once everything is fully operational, a ‘null series’ of about 10 to 20 board sets will be produced to ensure all issues are resolved both mechanically and electrically. Once this is validated, the final step will be to initiate mass production for the remaining 980 boards and order packing materials. While this sounds straightforward, there’s still considerable work ahead before production can commence.

Technical Details

The new board is based on AMD (Xilinx) technology, whereas the previous version relied on Altera. Despite careful preparation to ensure FPGA vendor independence, porting such a complex design has inevitably presented challenges, some of which have caused delays. However, there have been notable successes: the HDMI output worked on the first attempt, and a new scaler block for the VIC was developed, which scales its output to 1080p (Full HD) resolution. The results are impressive, with exceptional visual quality, and the analog video output is also functional.

Through some workarounds, access was gained to the on-board memory (128 MB DDR2), which manages everything except the 64K RAM and system ROMs of the Commodore itself. With this memory access, the U64 application was successfully run, and the Ethernet and USB functionality were confirmed to be working as expected. However, the memory controller provided by AMD (Xilinx) was found to be extremely slow, rendering cartridges unusable. To address this, the team had to delve deep into the chip’s architecture and design a custom DDR2 controller, similar to the approach taken with the Altera (U64) and Lattice (U2+L) products. The current focus is on coding the calibration algorithm for the memory, which will be integrated into a bootloader as part of the CPU subsystem. Once operational, this will enable programming of the on-board Flash chip, booting of the entire system, and further refinement from there.

Several areas of the circuit still require attention. For instance, analog audio is not yet functional due to the need to familiarize with a new codec chip. Additionally, the C64 keyboard scan logic needs to be rewritten, and the paddle circuit, tape controller, external cartridges, on-board speaker, and other components still need to be tested.

In parallel with the production of the null-series, the design of a factory tester will be necessary. Fortunately, much of the tester setup from the U2+L can likely be reused, which should reduce the workload compared to previous projects. However, as previously mentioned, there is still significant work to be done.