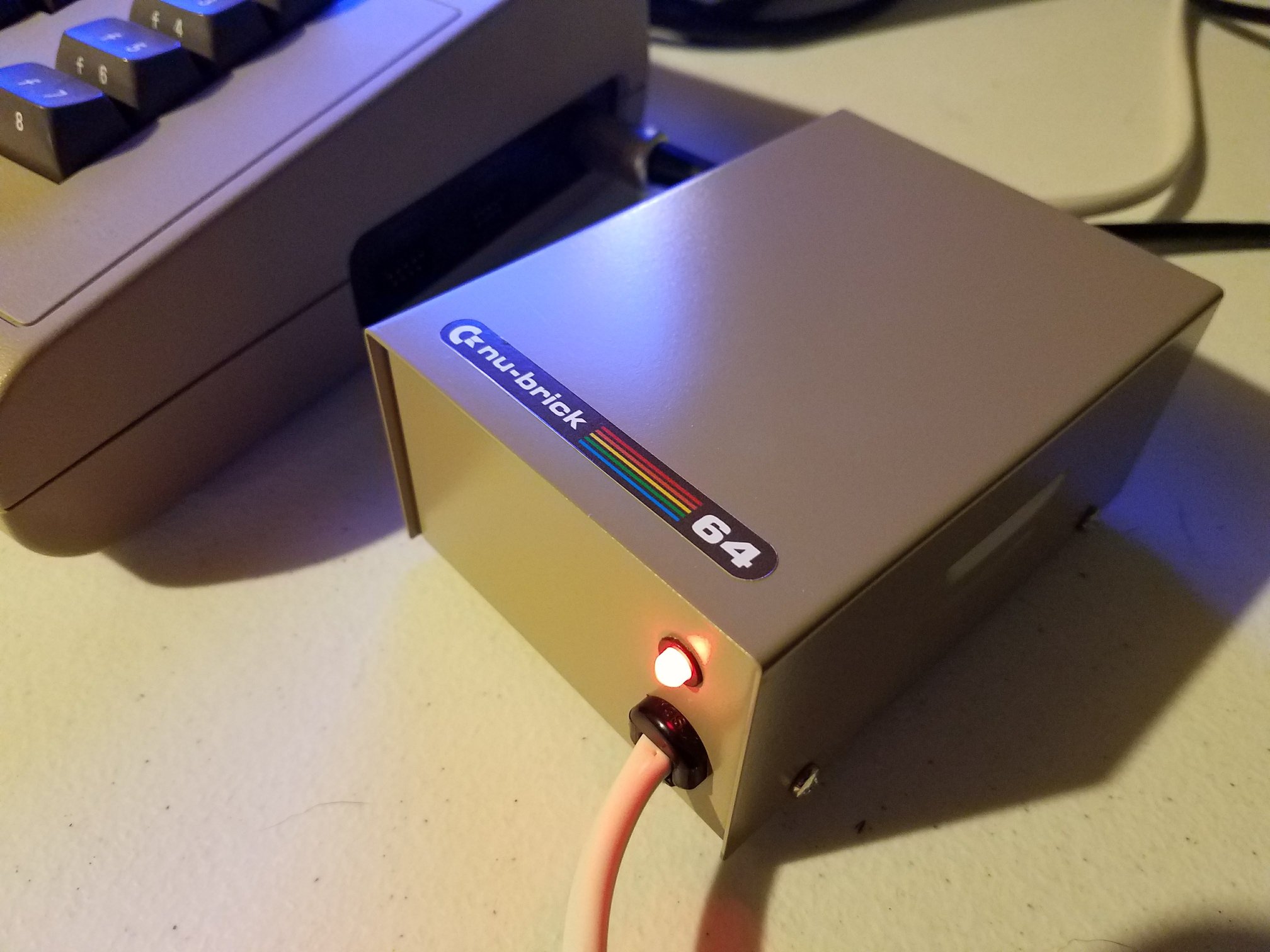

In a recent episode of More Fun Fixing It, Lee tackles a common but frustrating hardware problem: PLA socket issues in a faulty Commodore 64. This particular unit—one of four shown in a previous triage video—fails to boot, displaying a screen of corrupted graphics. After some testing, Lee suspects poor contact due to a bad single-wipe socket and short chip legs. The result? An intermittent and unreliable connection.

To fix the PLA socket issues, Lee walks through his process step-by-step. From prepping the board and desoldering the old socket to installing a clean dual-wipe replacement, every move is designed to restore the system’s stability. He avoids the shortcut of soldering the PLA directly to the board, noting that future owners will appreciate the ease of replacement should the MOS PLA eventually fail.

Diagnosing the Fault

Lee begins by demonstrating the fault—garbled screen output that changes when the PLA is pressed. This behavior points to poor contact, likely due to the single-wipe socket and short chip legs. Contact cleaner offers a brief fix, but the issue returns.

A Proper Socket Replacement

Instead of patching over the fault, Lee removes the old socket cleanly and replaces it with a high-quality dual-wipe version. He also inspects the board, trimming uncut resistor pack pins that were nearly shorting and noting inconsistent pin lengths across multiple ICs.

Successful Repair and Test

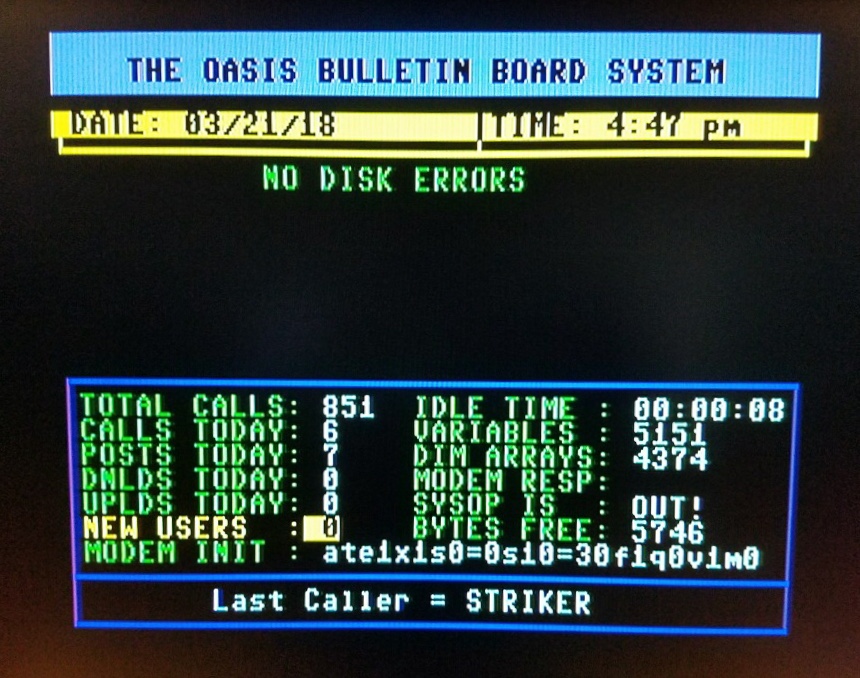

With the new socket installed, Lee reseats the PLA and runs full diagnostics, including the harness test. All tests pass. No more display corruption, and the PLA sits securely with no movement.